Assembly Order Tutorial

Assembly orders

Usage Scenarios: Merchants do not sell their purchased products directly to other customers, but rather "Process" them first, and then sell them after turning them into marketable assemblies.

For example: door and window manufacturers will process hinges, window frames, glass, etc. into windows for sale; there are also lamp manufacturers processing light sources, panels, brackets, etc. into lamps for sale and so on.

Function Introduction: Support to issue assembly orders to convert multiple products into a new one. Note: Assembly Orders belong to a service subscription product, and need to be purchased before the usage.

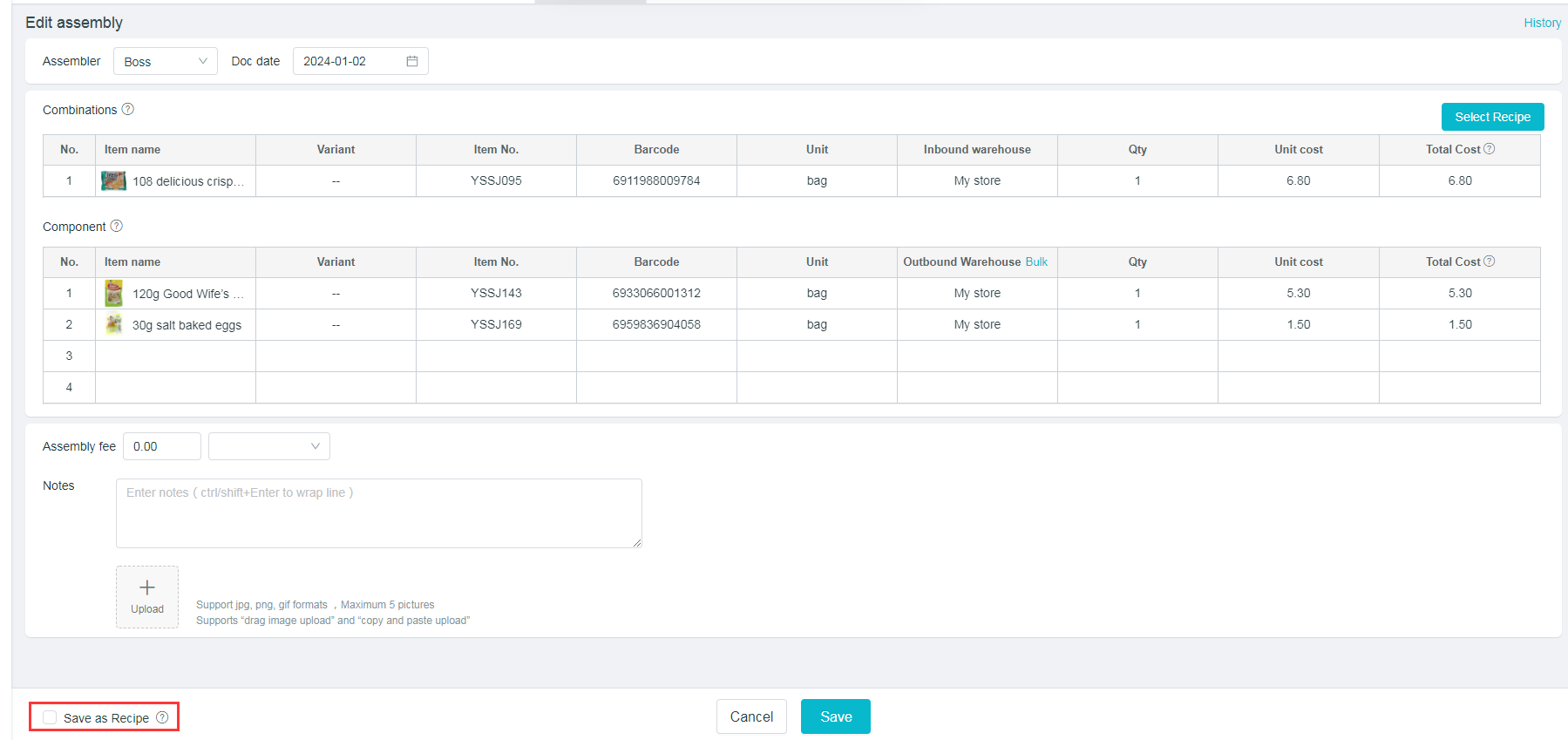

Add assembly orders

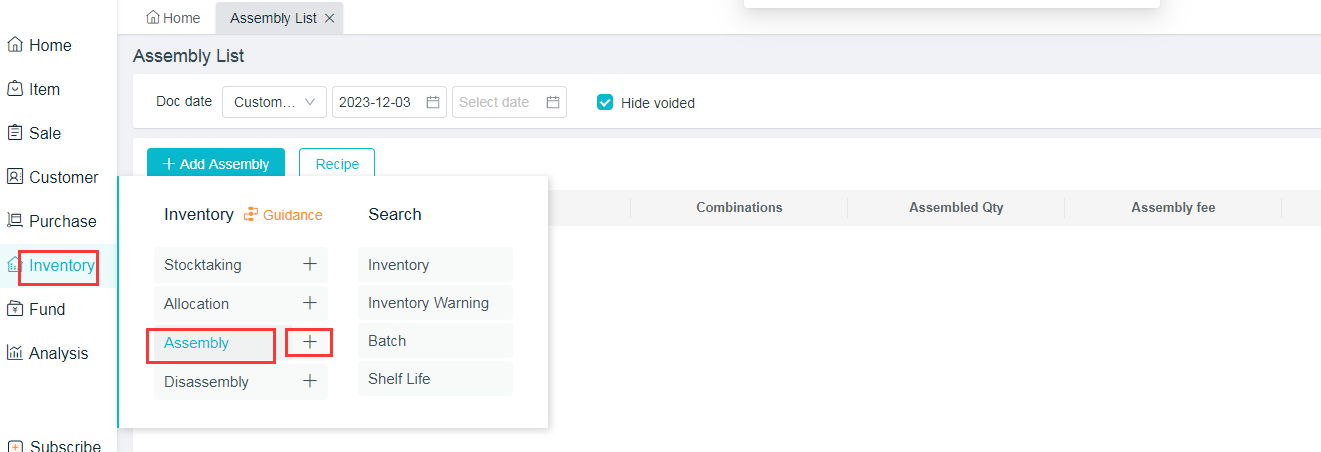

Operation Path: [Inventory] - [Assembly] - [+]

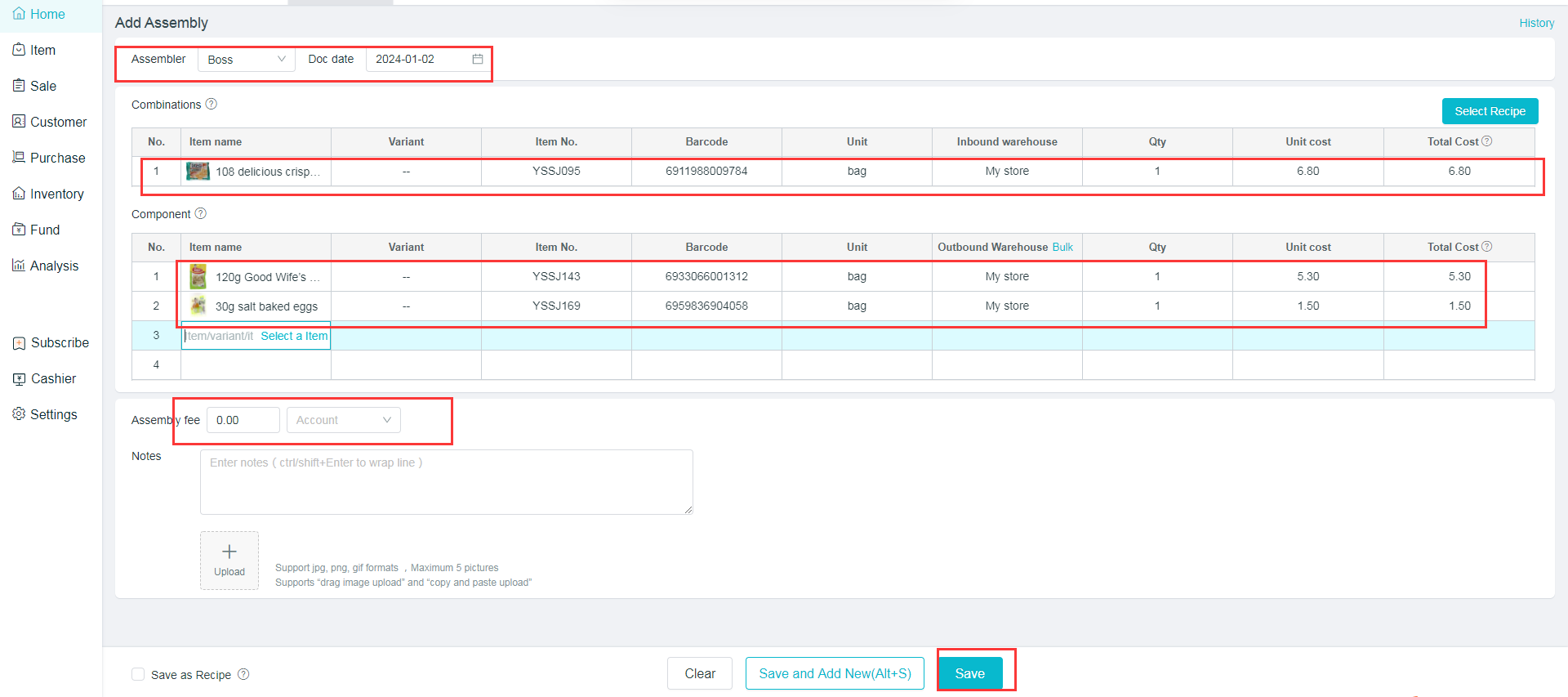

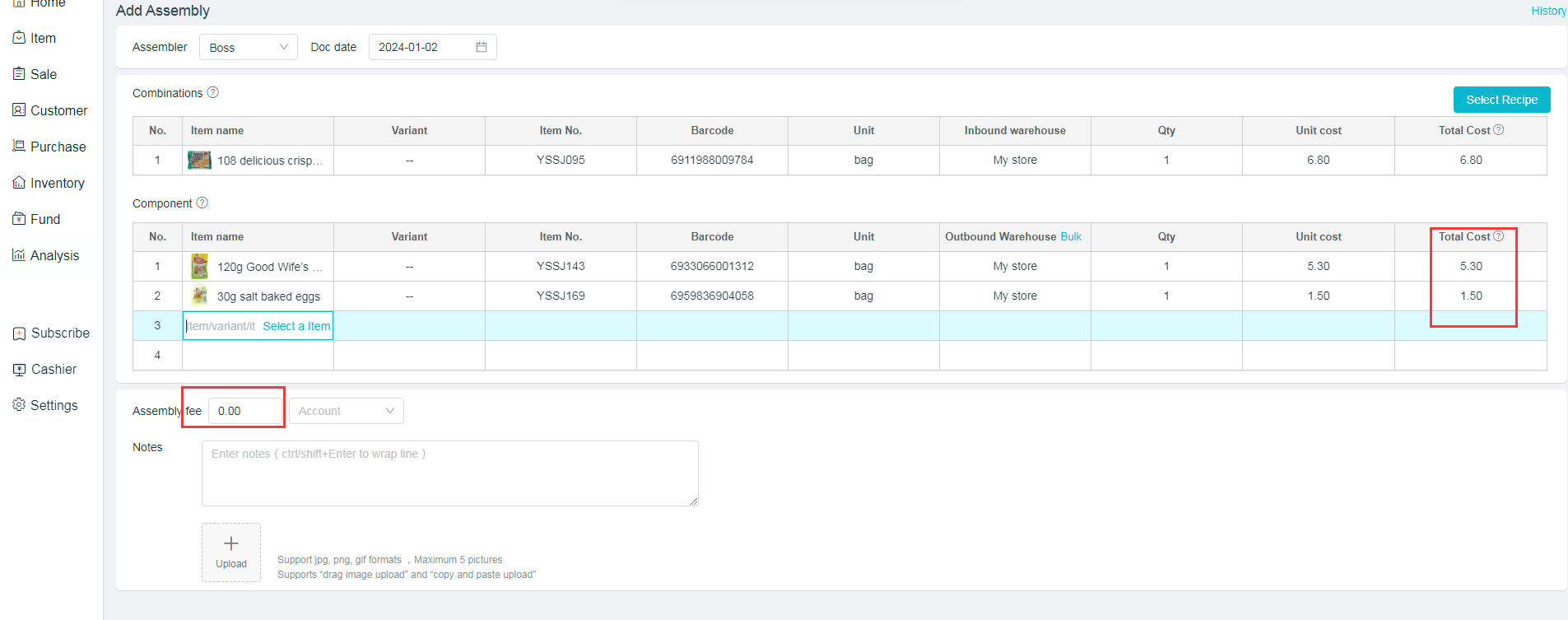

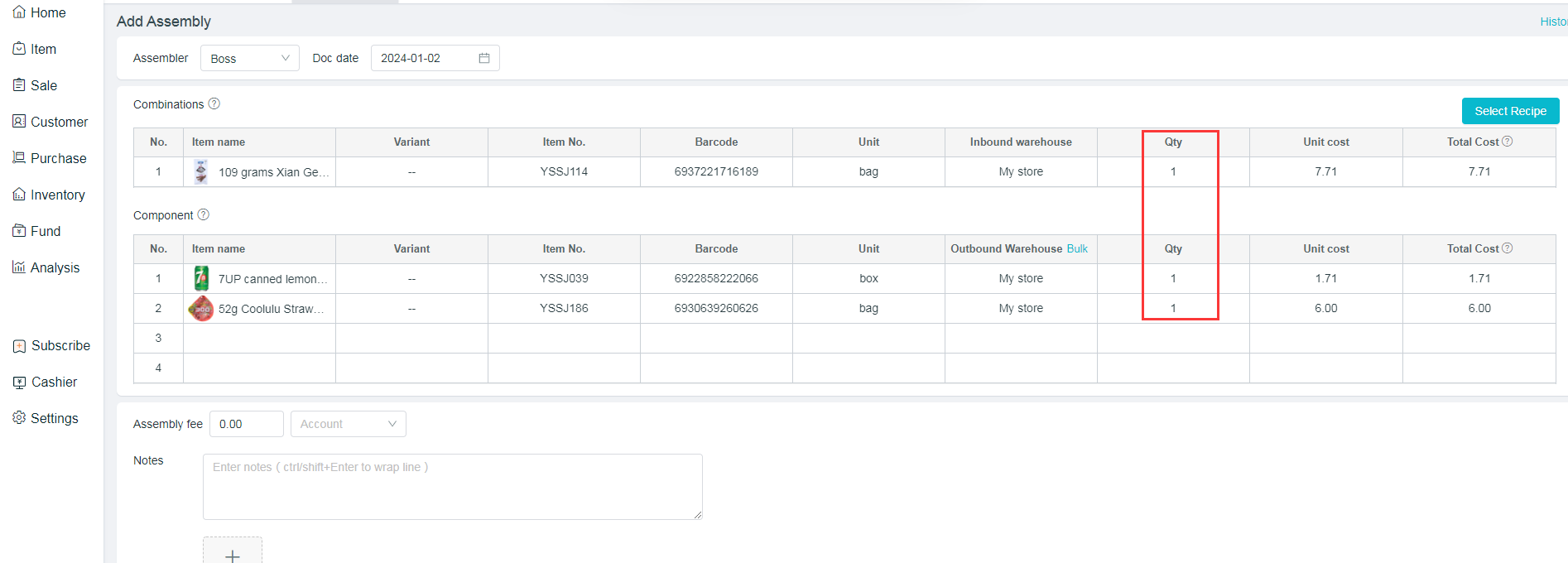

1.Select the assembler and the date;

2.Enter the information of combined products, and only a single product can be selected;

3.Select the information of sub-products, and multiple products can be selected;

4.Enter the assembly fees and select the billing account;

5.Click to Save

Note: After the billing is completed, the inventory quantity of sub-piece products will decrease (the cost is calculated at the purchase cost), and that of combined products will increase (total costs = sum of sub-piece costs + assembly fees)

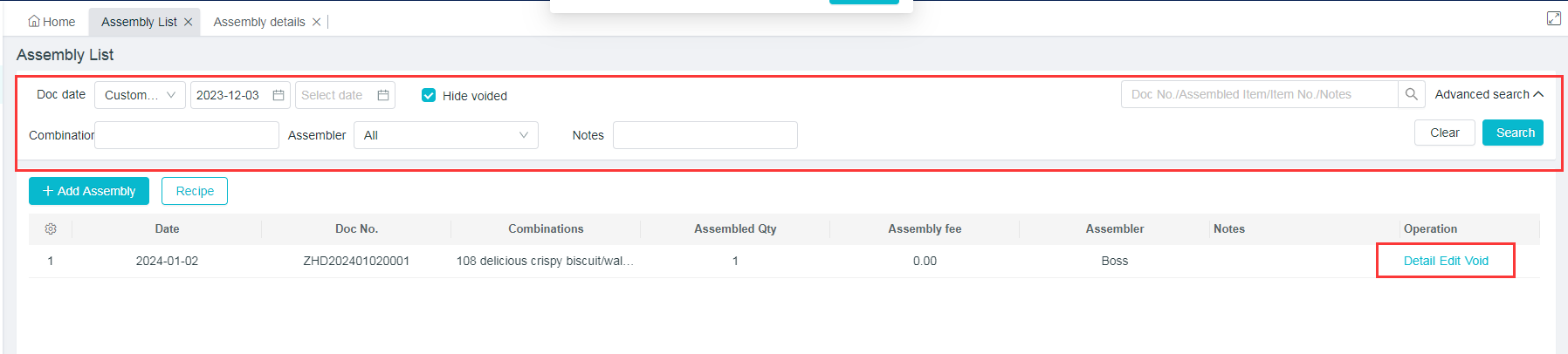

List of assembly orders

1.Support the selection of date, document number, name of combined products, notes, assembler for query.

2.Check “Hide the Canceled Documents”.

3.View, modify and cancel the assembly orders.

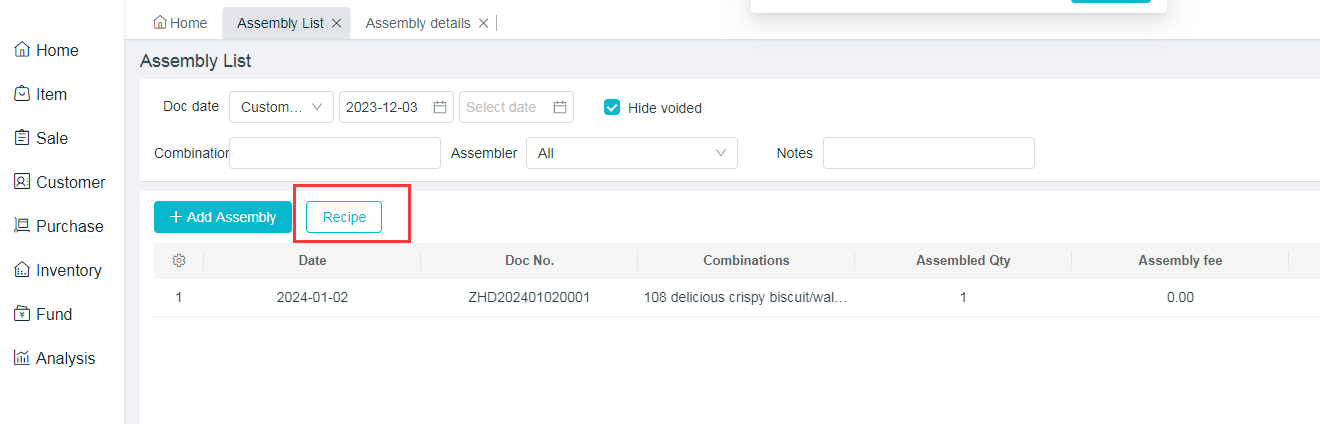

Formulation

Usage Scenarios: The amount of parts used for a finished product is fixed.The number of parts with an equal proportion will be consumed in each process.Other names include: BOM sheet, materials list.

Function Introduction: Support to create the formulation in advance for quick application of billings.

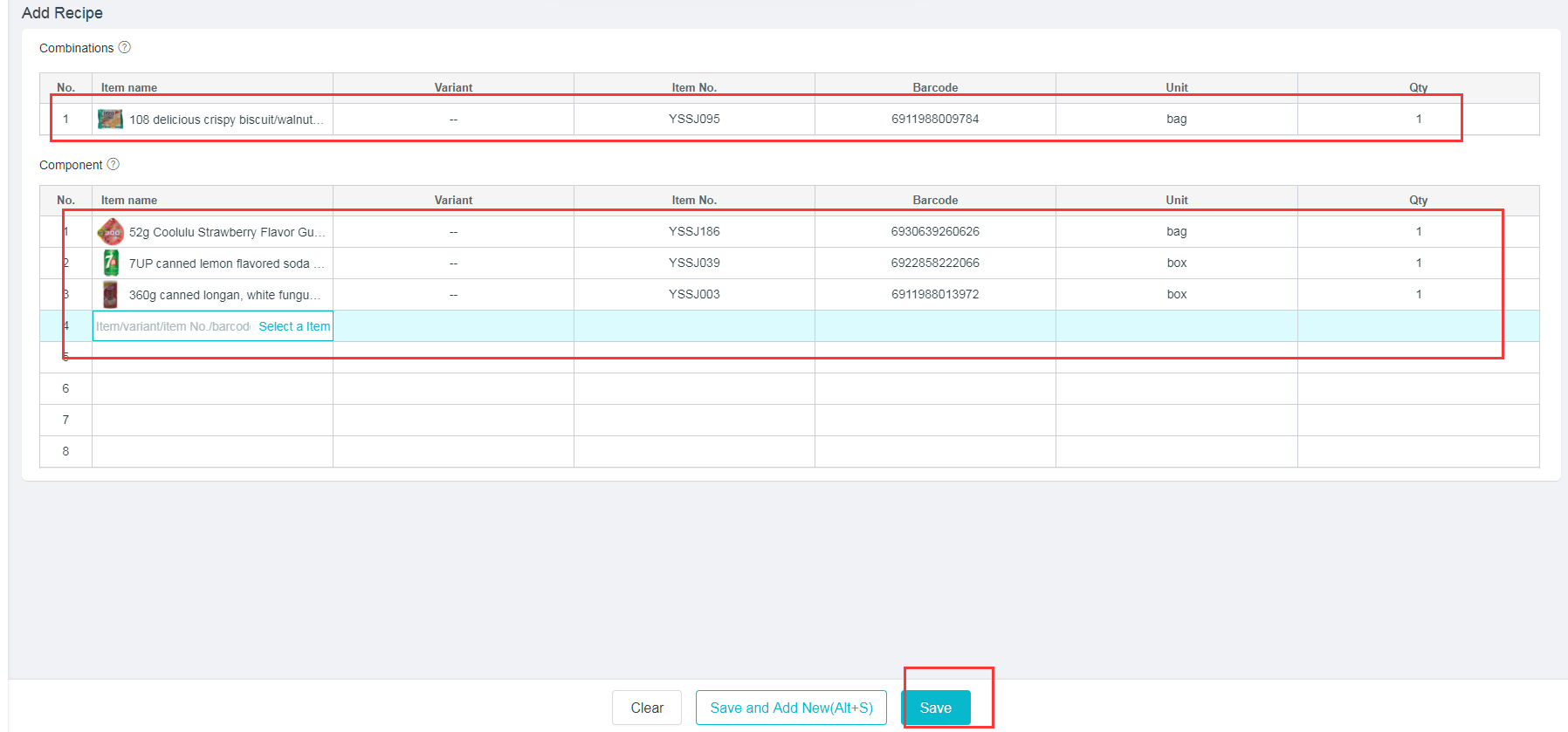

Add Formulations

Operation Path: List of Assembly Orders - [Formulation] beside the “Add Assembly Orders” - Add Formulations

- Select the information of combined products;

2.Select the information of sub-products;

3.Click to Save.

Or check to save as Formulation when an assembly order is added.

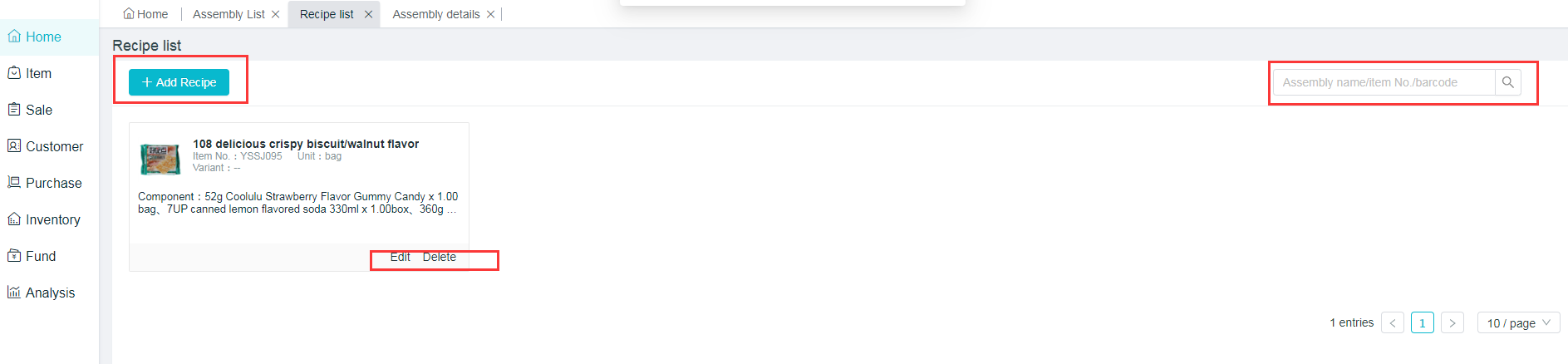

List of Formulations

1.Formulations can be added;

2.Enter the name of combined products / product number / bar code to query the formulation;

- Click on “Modify” under the Formulation to modify the information of formulation;

4.Click on “Delete” under the Formulation to delete it.

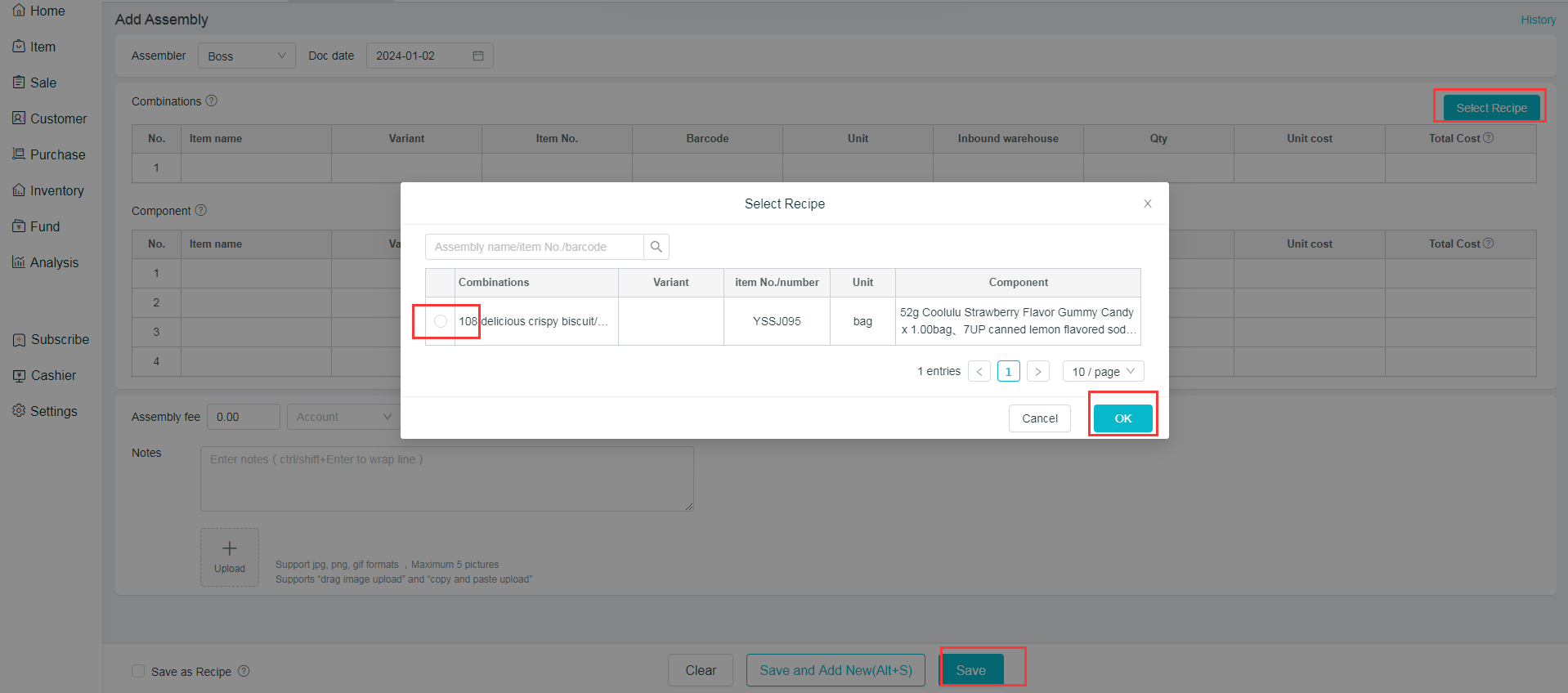

Select formulations

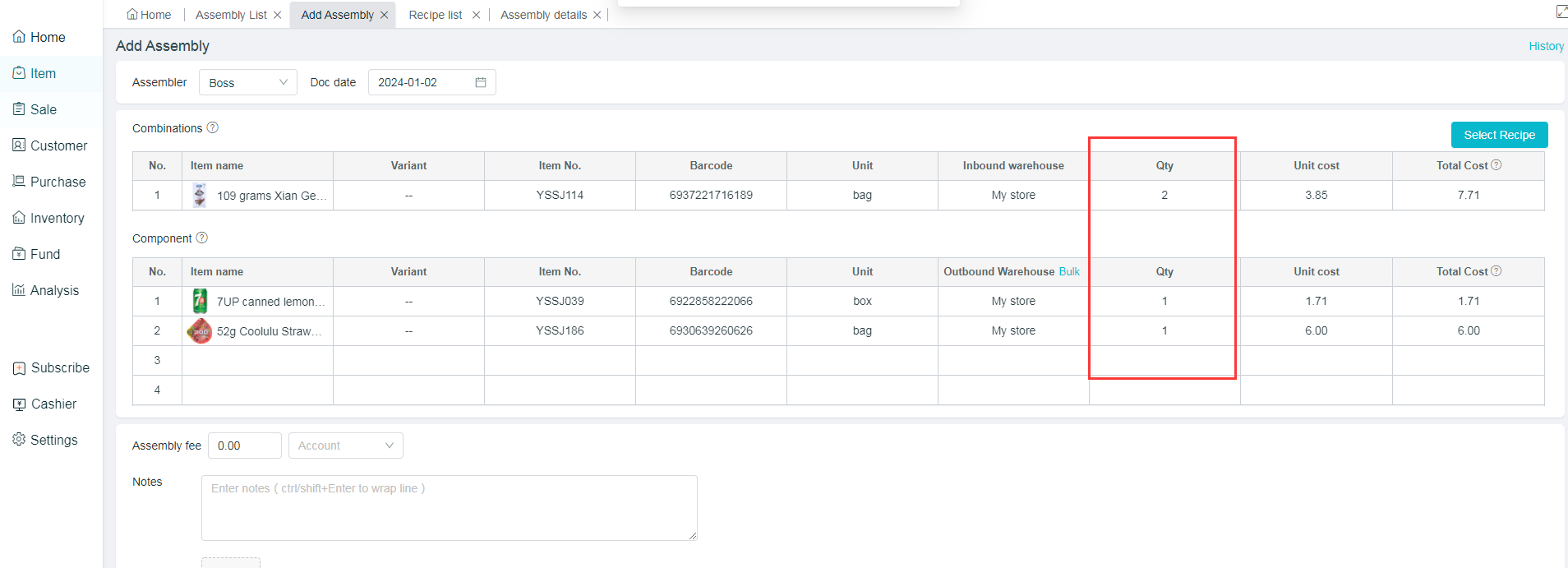

1.Add the Assembly Order Interface, and select the Formulation at the top right corner.

2.Change the quantity of combined products, and the quantity of sub-pieces will be changed at equal proportion;

3.Modify/Delete the quantity of sub-piece products, and the formulation correlation will disappear. Then go to change the quantity of combined products that of sub-piece products will not be changed at equal proportion.